Your new post is loading...

Your new post is loading...

|

Scooped by

Prentiss & Carlisle

October 30, 2018 12:09 PM

|

For forest companies like TimberWest, the health of the trees and associated ecosystems are paramount. From seedling to maturity, the trees must be monitored, and any problems addressed. The way in which this monitoring happens is changing dramatically through the convergence of new sensing technologies such as LiDAR and the ability to deploy sensing technology using drones. What was once used only for air space and meteorological research, LiDAR – which stands for Light Detection and Ranging and is commonly referred to as airborne laser scanning – is now being used for forest research to more accurately examine everything from the height and diameter of trees to ground terrain evaluation and plot-level wood volume estimates. In the just-released video Forest for the Trees: How technology is transforming B.C.’s forest industry, University of British Columbia (UBC) forestry professor Dr. Nicholas Coops emphasizes LiDAR and drone use are just two more recent examples of the forest sector's technological revolution, and the types of technology incorporated into every-day forest management. “This link between technology and forestry has always been there. I think now it just happens to be exploding at the moment,” Coops says. Coops explains LiDAR technology can be used with airplanes or drones and involves sending pulses of light down to the ground that bounce back and mirrors the data captured into images that allow forest planners to measure the topography, depth, height, slope and other values of the land being surveyed. Domenico Iannidinardo, TimberWest’s vice-president of sustainability and chief forester, says he sees great value in LiDAR technology and drones when it comes to forest management and planning. LiDAR can provide a wide range of enhanced ecological applications such as evaluating microhabitat diversity and watershed modelling. Through the use of LiDAR, forest planners can rapidly and accurately produce three-dimensional data-sets, which allows them to better assess road building opportunities, stand value and wood quality, resulting in more efficient inventory management.

|

Scooped by

Prentiss & Carlisle

July 13, 2018 4:58 PM

|

Swedish self-driving truck startup Einride is out with another eye-catching prototype. Much like the company’s first autonomous offering, the new T-Log is all-electric and completely driverless, and it completely lacks a front cab for human drivers. But unlike the T-Pod, the T-Log comes equipped with off-roading capabilities and is designed for one specific purpose: hauling tons of gigantic tree logs.

Unveiled on Thursday at the UK’s Goodwood Festival, the T-Log is more powerful than the T-Pod, and it’s designed to carry up to 16 tons of cargo. It can also navigate dense, uneven forest roads, the startup claims, making it ideally suited for logging purposes.

"Self-driving on dirt and gravel roads"

How exactly this truck with no human driver can handle unmarked, often dirt and gravel roads is pretty interesting. Most self-driving vehicles rely on a suite of sophisticated sensors, mapping data, and deep learning capabilities to handle the driving responsibilities. But even then, a majority of operators will stick to highly predictable environments, like suburban communities with robust roads and signage. (MIT recently proved that self-driving cars can successfully navigate rural, unmapped roads.)

|

Scooped by

Prentiss & Carlisle

June 1, 2018 11:29 AM

|

Blockchain SaaS startup Bext360, which provides traceability for coffee products with a Coinstar-like device for farmers, announced Friday that it has completed its $3.35 million seed round. Investors in the startup include SKS Ventures and Plug and Play Ventures.

Bext360's software keeps track of commodities by identifying and making an electronic token for each one. This unique ID provided to each coffee bean produced enables the company to trace it through the entire supply chain, from the farmer all the way to the cup you drink at a coffee shop. By tokenizing the coffee beans, the company is also able to provide payment to farmers upfront, so they aren't left waiting for weeks or sometimes even months to be paid for their products.

***

Now that the company has proven its technology with coffee, it's using part of this seed money to expand into other verticals. According to its CEO Dan Jones, the company will be partnering with Fashion For Good to do a pilot program with cotton later this year, as well as a pilot for palm oil. Future expansion will include nuts, seafood and potentially even minerals and timber.

"We had to pick verticals in line with current mission and verticals that had huge impact on environment," Jones said.

***

Moving into these new verticals will provide new challenges for Bext360. Cotton, for example, can't be as easily sorted as coffee beans, so the company is working on alternate ways to trace it. According to Jones, the company is working with biomarker companies as well as developing its own markers in-house. These technologies include possible ways to track cotton such as synthetic DNA strands or fluorescent tags.

|

Scooped by

Prentiss & Carlisle

January 2, 2018 11:14 AM

|

In the quest to produce affordable biofuels, poplar trees are one of the Pacific Northwest’s best bets—the trees are abundant, fast-growing, adaptable to many terrains and their wood can be transformed into substances used in biofuel and high-value chemicals that we rely on in our daily lives.

But even as researchers test poplars’ potential to morph into everything from ethanol to chemicals in cosmetics and detergents, a commercial-scale processing plant for poplars has yet to be achieved. This is mainly because production costs still are not competitive with the current price of oil.

A University of Washington team is trying to make poplar a viable competitor by testing the production of younger poplar trees that could be harvested more frequently—after only two or three years—instead of the usual 10- to 20-year cycle. These trees, essentially juveniles compared with fully grown adults, are planted closer together and cut in such a way that more branches sprout up from the stump after each harvest, using the same root systems for up to 20 years. This method is called “coppicing,” and the trees are known as poplar coppice.

The team is the first to try converting the entire young tree—including leaves, bark and stems—into bio oil, a biologically derived oil product, and ethanol using two separate processes. Their results, published this summer in two papers—one in ACS Sustainable Chemistry & Engineering and the other in Biotechnology for Biofuels—point to a promising future for using poplar coppice for biofuel.

“Our research proved that poplar coppice can be a good option to meet the cheap, high-volume criteria of biofuel feedstock,” said lead author Chang Dou on both papers, a doctoral student in the UW’s Bioresource Science and Engineering program. “Our findings are significant for the future biofuel industry, and the ultimate goal is to make poplar coppice biofuel a step closer to the pump.”

|

Scooped by

Prentiss & Carlisle

November 20, 2017 10:52 AM

|

Paper and forest products aren’t going away in the age of the smartphone and tablet, but the industry is shifting its focus to new use cases driven by digitization. In this episode of the McKinsey Podcast, Peter Berg, director of knowledge in McKinsey’s Paper & Forest Products Practice, and Oskar Lingqvist, senior partner and global leader of the practice, speak with McKinsey’s David Hunter about areas of growth in paper and forest products, including potential innovations in packaging and the overall value chain.

***

David Hunter: ... And digital is giving as well as taking away. While demand for newsprint paper is being lost as readers move online, the ever-increasing migration by consumers to make purchases online is generating demand growth for transport packaging. These are just a couple of the strands of the major changes under way. Oskar and Peter, how has the big picture evolved over the past 15 years? Is paper demand in irreversible decline and going to disappear? If you look at this going forward, where do we expect it to end up? We see very different growth paths and growth trajectories for the different segments of the paper and forest-products industry. Peter Berg: ... If you think of printing and writing papers, we see the decline probably continuing. It is quite unclear whether there will be a floor somewhere, where you reach an equilibrium, where we’re still using papers for reading and writing but at a lower level than we do today. Or will they disappear completely because people, particularly younger generations, have become so used to reading and writing and doing everything in terms of communications through electronic means? David Hunter: Given these trends, what sort of initiatives are top of mind for executives in the industry today? What are the major challenges facing the paper and forest-products industry? Oskar Lingqvist: ... We also see an increased focus on having access to the source of paper and forest products, which is the fiber. Essentially, while you see papers in decline or packaging or tissue growing, if you map that out, there’s actually going to be more scarcity or need for attractive fibers, especially those that we can breed in the northern parts of the globe. So getting access to the right raw materials is still very important. If we want to mention one more theme, which is, of course, not unique to the pulp and paper or forest practice, it is the wave of various digitization initiatives that are happening. Why so? One, because any challenged industry will, of course, look to efficiency and effectiveness to drive out cost and increase performance. But also, which is maybe not so well understood, the paper and forest-products industry is one of those industries that’s very well set up—because of relatively advanced technologies, because of very continuous processes in manufacturing—to handle some of the new digital technologies that are available. Peter Berg: ... The second one on fiber supply and the importance of having access to cheap and good fiber, as Oskar mentioned, is almost a bit of a tug-of war-coming up between different kinds of fibers. We have a certain situation in recycled fiber. If you take the average, across the world and across all products, roughly half of the fiber raw material in a paper product is recycled somehow. You have that, as opposed to virgin fiber, fresh fibers, of different kinds. In addition, you have new technologies and new product developments around what people call nanofibers that may add to this tug-of-war and how you use different kinds of fibers in different ways. That’s an incredibly exciting development that requires a bit of time to see how that’s going to evolve.

***

David Hunter: I’m going to switch direction slightly. You’ve mentioned that there’s a need for new virgin fiber. Where is the industry looking in the world to develop that resource? Peter Berg: That’s a very good question, and it’s a critical question for many pulp and paper companies. If you look historically, what we’ve seen over the last decades is that—or go even further back, if you wish—most of the paper production in the world was in the Northern Hemisphere, close to the forests of the Northern United States, Canada, the Scandinavian countries, where you have a lot of spruce and pine trees, out of which you made sawmill products, assorted wood products, as well as paper. Over time it shifted also to the Southern Hemisphere—for example, to South America, to Brazil—where it’s easier to quickly grow trees, and in this case, it’s acacia and eucalyptus trees that have a tendency of growing faster than the spruce and pine trees of the Northern Hemisphere. There’s been, over the last decades, a significant movement for some kinds of fibers, the kinds of fibers that come from leaf-bearing trees down in the Southern Hemisphere. This is often in the form of plantations, so huge plantations on flatlands in, say, Brazil or in more hilly lands of, say, Chile. Going forward, the industry needs to look both for more such opportunities but also, to one of Oskar’s earlier points, for fibers of more strength, of longer fibers, from the kinds of trees and forests that you have up in the Northern Hemisphere. So there is a need to more efficiently, in an environmentally correct way, use the forests of the Northern Hemisphere. This may be in Russia, for example, which has an enormous stock of these kinds of forests throughout its area. It could be in North America or the northern parts of Europe. Oskar Lingqvist: When we look at that equation that Peter just described, you could take one of two stands, or maybe a combination thereof. One is to say, well, if we project out and we look at what will happen in terms of needs per segment, and what might happen even to topics we haven’t discussed, which is the quality of the fiber we recycle in our day-to-day products, one would say we could be looking at a quite big or substantial scarcity of the type of fiber that we know in the Northern Hemisphere, essentially what we call soft wood. You could take a slightly different stand and say, well, it’s in those types of situations that technology comes to the forefront, and we see development, and we might see new mixed species or developed species increasingly also coming through what we call hardwood, so basically what comes from the plantations and mainly through eucalyptus. Who knows exactly where on that scale we will end up, but, again, having access to the right fiber and, if you’re in the industry, making the right bets on fiber become increasingly important.

|

Suggested by

David G

June 28, 2017 11:34 AM

|

|

Scooped by

Prentiss & Carlisle

February 15, 2017 6:34 PM

|

Mahone Bay-based startup WoodsCamp Technologies is leveraging open data to reinvent — and reveal fresh insight into — Nova Scotia’s forestry industry.

WoodsCamp Technologies is an online timber brokerage that uses free ‘open’ provincial government data to connect woodlot owners, loggers and sawmills in a way that increases both efficiency and sustainability. In other words, WoodsCamp gets timber to the right place at the right time, and at a price that works for everyone.

The company had a great 2016, says Alastair Jarvis, who — along with Will Martin — launched WoodsCamp officially in May of that year.

***

The main WoodsCamp product for landowners uses ‘open’ data to quickly tell woodlot owners what’s growing on their property. This data, gained by remote sensors, represent a digital catalogue of what trees grow across the province. WoodsCamp ascribes a score to each lot, to assess the value of its contents. That means owners selling their timber have an idea of the value, even if they live thousands of miles from the woodlot. If they sell timber through WoodsCamp, the company gets a cut. And for the loggers and the pulp and timber mills who buy the wood? WoodsCamp offers the prospect of a more stable, sustainable and efficient supply chain.

But perhaps most importantly, says Jarvis, December saw WoodsCamp dispatch its 1,000th WoodsCamp report on privately held Nova Scotia land — a milestone representing, he says, approximately three per cent of the province’s 30,000 private landowners, in his well-researched estimate.

***

Meanwhile, says Jarvis, the data showed also that while Nova Scotia landowners are definitely motivated by money, financial gain is often not their primary goal.

“Most often, landowners say they want to make their forest healthier over time,” he says.

***

Going into the rest of 2017, both men remain focused on proving their idea can work here in Nova Scotia — before eventually taking it into eastern North America and Europe.

Says Jarvis, “We’re looking to scale globally in regions where a distributed and fragmented forestry supply chain persists, and where the network of human relationships that made the market work for a generation is now disintegrating.”

|

Scooped by

Prentiss & Carlisle

January 18, 2017 11:39 AM

|

Enviva Holdings LP, the world’s largest producer of wood pellets, recently publicly released the first data from its groundbreaking Track & Trace (T&T) program. T&T is a proprietary system that enables Enviva to track every truckload of wood the company procures from the forest back to its source, providing a detailed understanding of the characteristics of the wood the company uses. Demonstrating an unmatched commitment to transparency, Enviva is now making that information available to the public. *** Before selling wood to Enviva, a supplier must provide detailed data on the specific forest tract being considered for harvest, including each individual tract’s precise geographic location, acreage, forest type, species mix, age and the share of wood from each harvest that goes to Enviva versus other consumers. Enviva does not accept any wood from a harvest without this information, and the company records the data and verifies the accuracy of its procedures through third-party audits. T&T data are presented in two ways. First, the Forest Trend Map is based on time-series data from the U.S. Forest Service and displays changes in overall forest conditions in the Southeast U.S. and in each of Enviva’s forest supply areas. Second, the Enviva Wood Supply Map provides detailed information on actual timber harvests around each of Enviva’s facilities during the first half of 2016. Data include harvest site, landowner type, forest type, harvest type, years since last harvest, the number of acres harvested and the percentage of the harvest volume provided to Enviva for wood pellet production. The first T&T public release includes Enviva wood purchases from January through June 2016.

|

Scooped by

Prentiss & Carlisle

August 11, 2016 2:27 PM

|

Nuveen Investments has rolled out a new platform that will expand access of its alternative investment lineup to wealthy individuals working with financial advisers. Nuveen, an operating division of TIAA Global Asset Management, already manages $140 billion worth of alternative investments for institutional investors in products including real estate, agriculture, timber, agribusiness, and private equity. But the addition of a technology-driven platform is designed to expand that access to qualified clients of financial advisers and family offices.

***

The Nuveen platform, which provides advisers access to alternative products at TIAA Global, deals with the kinds of private investment products and partnerships that require investors meet certain net-worth minimums. But, as Mr. Perry explained, technology is making it easier for advisers to gain access to a variety of unregistered products. Nuveen has engaged technology provider Artivest to create a white-label platform to provide access to private alternative investments from Nuveen/TIAA. The products had previously not been available to individual investors.

|

Scooped by

Prentiss & Carlisle

July 18, 2016 1:04 PM

|

The Brazilian Forest Service released an application for smartphones and tablets that uses QR codes to help verify the legality of traded timber, according to Fordaq.

An agent using the application will be able to scan QR codes placed onto bundles of wood that contain information about that specific shipment that was submitted to Brazil’s Chain of Custody System by logging companies operating within the country’s sustainable forest management regime.

The forest service told Fordaq, “The aim of this application is to provide transparency on forest concessions activities to improve the confidence of timber buyers that the material being offered for sale can be tracked through the system to demonstrate legality.”

The data can produce, among other things, geographic coordinates for the logs and sawn wood.

The app is the latest in a number of technological solutions to fighting the illegal timber trade. HF previously reported on a team of scientists at the United States Forest Products laboratory who have developed a device that can detect the species of logs in a matter of seconds. The scientists behind the project hope it will catch illegal timber smuggled under legal species names.

|

Scooped by

Prentiss & Carlisle

March 14, 2016 12:33 PM

|

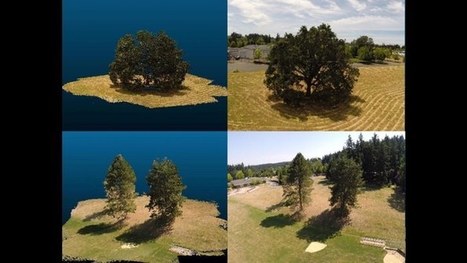

Considering that it takes hundreds of years for forests to grow, it can be difficult to assess how they'll be affected by climate change in the long term. To address that problem, researchers at Washington State University have created the world's first computer simulation capable of growing realistic forests, using the model to predict how things like frequent wildfires or drought might impact forests across North America.

The new computer simulation allows scientists to grow a virtual forest over the period of a few weeks. Known as LES (after the Russian word for forest), the system simulates the growth of 100 x 100 m (330 x 330 ft) areas of vegetation, that are then scaled up to simulate entire forests. It's more complex than any previous systems, simulating both canopy structures and intricate root systems for each tree. Each leaf competes for sunlight, while beneath the virtual earth, the organisms' roots compete for water resources.

In order to ensure that the model accurately represents real-life forests, the researchers turned to the US Department of Agriculture's Forest Inventory and Analysis program, as well as other forestry databases. They also worked with the US Forest Service to fly drones over and around forests, imaging them to gather further information and develop 3D models, allowing for more accurate vegetation and tree distribution.

|

Scooped by

Prentiss & Carlisle

September 10, 2015 11:40 AM

|

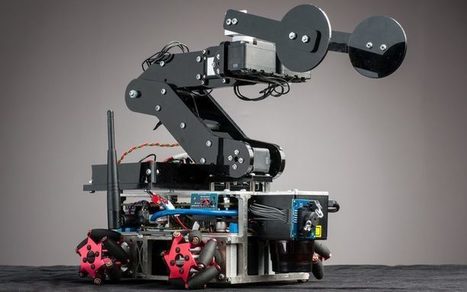

Nick Birch and Tyler Rhodes hope they are unleashing a bit of forestry’s future in a recently cleared patch of forest in the hills above Maple Ridge: the Tree Rover, a robot capable of planting trees.

The concept is pure R&D at this point — think of it as pre-startup, in the terminology of tech business. The third-year electrical engineering students are pursuing it as part of an entrepreneurial co-op term at the University of Victoria. The exercise is to take an idea and, in four months, create a project that results in a tangible prototype that can be built upon. ***

In the current iteration of Tree Rover, the computer-controlled planting mechanism they’ve devised — the heart of the invention — is on top of a bright-orange four-wheeled cart, but they envision a future version on a four-legged vehicle better able to navigate the rugged terrain of a cutblock in a B.C. forest.

***

On a recent Tuesday, they brought their prototype to the University of B.C.’s Malcolm Knapp research forest to give a demonstration to the research coordinator, Ionut Aron, and to scout out good spots for a proper test next spring.

For now, the Tree Rover operates mostly by remote control, with some autonomous functions, so Birch toggles keys on his laptop computer to bring it to life and drive it over to a prepared patch of dirt.

A seedling from the Plexiglas hopper on top drops into a hollow spike at the heart of the rover. Then, with a mechanical hiss of compressed air, the machine drives the spike into the ground. Another arm swings down to tamp the plant more firmly in place and it rolls off leaving the bright green shoot behind it.

***

“Obviously it’s a prototype,” Aron said. “In it’s current form, it wouldn’t be able to plant trees in cutblock.” However, if the concept can be developed, he said automated systems might be able to improve productivity in tree planting, or have applications in remote locations.

|

Scooped by

Prentiss & Carlisle

July 22, 2015 9:21 AM

|

The days of the axe and the cross-cut saw are long gone. But if you don't work in the timber industry, you probably wouldn't know that, increasingly, a new breed of bushmen don't even use a chainsaw.

Logging in the native forests on the mid north coast of NSW is done in the air-conditioned comfort of a harvesting machine. It looks like a tracked excavator, with a large mechanical arm that locks on, cuts and even debarks the trees.

Fallers know exactly where they are, thanks to a GPS. There's also an iPad stuck by suction cup to the front window, loaded with an interactive map produced by a radar-like system that uses light instead of a radio wave.

It's called LIDAR, which stands for light detection and ranging. The light 'pulses' from the aerial pass of a plane produce a map that is so detailed you can see a big picture of the landscape at any scale ... the ridges and rivers, rocky outcrops and swamps. But you can also zoom in to identify individual trees that get marked on the map: an 'H' for a habitat or hollow bearing tree, 'R' for a recruitment tree, 'K' for koala habitat tree or 'E' for eucalypt feed trees, which provide a flowering resource over winter for arboreal mammals. After logging, at least six of these feed trees are kept across every two hectares.

|

|

Scooped by

Prentiss & Carlisle

July 17, 2018 11:47 AM

|

Forest-products companies plan to increase their investments in digital technologies over the next three years, in part to protect their market share and competitive advantage, according to a new report from Accenture.

Based on a survey of 200 executives at forest-products companies in 10 countries, the report, “Forest Products: The shift to digital accelerates,” also found that cybersecurity remains a concern for these companies, with only a minority able to counter attacks effectively, thereby prompting data-security concerns.

The study focused on forest-products companies with global annual revenues greater than US$500 million and that currently leverage digital technologies and/or are pursuing digital transformation. The survey was fielded between October and November 2017 and included executives from companies headquartered in Australia, Brazil, Canada, Finland, Indonesia, Malaysia, Norway, Singapore, Sweden and the US.

Among the report’s key findings: - More than four-fifths (82%) of the executives surveyed said their organizations are investing more or significantly more in digital technologies than they did in the previous financial year.

- An even greater number (88%) expect to increase their overall digital investment over the next three years.

- Among the top three technologies cited for digital investment, the most popular were: big data/analytics/edge computing; artificial intelligence (AI) / machine learning (ML); and advanced process control, cited by 46%, 41% and 38% of respondents, respectively.

|

Scooped by

Prentiss & Carlisle

June 28, 2018 10:09 AM

|

Digital technology is revolutionizing industries around the globe, from manufacturing to healthcare. Even agriculture is undergoing enormous change due to technologies like variable-rate fertilization and automated harvesting. Forestry, on the other hand, has lagged behind most other industries in the adoption of digital technology. This, however, is finally starting to change. Studies are already showing productivity increases in general agriculture at rates of 5 to 25 percent annually, with returns on investment of one to two years for digital technology (depending of course on many factors, such as farm size, crop selection, and other conditions). Analogous gains are not merely on the horizon for forest products but are also being realized by some pioneers today. The size of these gains is comparable only to the shift from animal-powered to mechanized processes and, in food farming, the Green Revolution of the 1960s. That said, in forestry-management science, digital solutions currently confront a system that still operates largely on the basis of fundamentals developed by Hans Carl von Carlowitz more than 300 years ago.1 Processes are highly manual and analog, with “broad-brush” management prescriptions. Introducing advanced technology in forest management faces several challenges: - There is little corporate involvement in forestry; 76 percent of forests globally are publicly owned,2 and most of the remainder are held by small private owners (who typically hold, on average, less than one hectare, or roughly two-and-a-half acres).

- State and other public forest owners tend to be relatively conservative in their management style and, to a greater extent than private enterprise, need to balance diverse objectives for commercial performance with social and environmental goals.

- Many private forest owners have operations characterized by a lack of scale and expertise required to adopt the latest technologies.

- Large-scale commercial forests, from eucalyptus plantations in South America to managed natural forests in Europe and North America, are in remote and rugged terrain, presenting many challenges for adoption of new technologies.

- While a wide range of precision forestry technologies exists, relatively few practical examples are up and running, and few understand how the technologies translate into real use cases.

|

Scooped by

Prentiss & Carlisle

March 30, 2018 9:46 AM

|

Forest and Wood Products Australia have produced a new report that examines remote controlled and autonomous machinery in forestry. The report was compiled Rien Visser, of the School of Forestry, University of Canterbury, New Zealand. Logging provides some excerpts from the document. Technology development, in terms of both capability and cost-effective integration, is moving at a fast pace. While advanced robotic systems are already commonplace in controlled workspaces such as factories, the use of remote controlled or autonomous machines in more complex environments, such as for forest operations, is in its infancy.

While technology integration and automation in forestry equipment are commonplace, the report focuses on equipment developments and opportunities where no operator is in the machine. The simplest form is remote control of the machine where the operator, typically in clear line-of sight, will work with wireless controls. While teleoperation is simply a more technical term for remote control, often implied is that the operator works from a virtual environment with live video and audio feedback from the machine. Since teleoperation provides a similar operator experience to working in the machine, it is relatively easy for an operator to transition to teleoperation.

For both systems the machine operation is typically slower, significantly so if the task is complex, and will not be adopted in forest operations strictly based on productivity improvements. However, benefits can quickly accrue when: (a) operator safety might be compromised, (b) where a full-time operator would be underutilised, or (c) where work sites are onerous to reach or suitably qualified operators are hard to find

|

Scooped by

Prentiss & Carlisle

December 15, 2017 11:58 AM

|

Some of the most dangerous and labour intensive jobs in the primary sector could soon be done by robots. Researchers from Lincoln Agritech, Scion, and several universities around the country are working to develop robots that can be trained to work alongside people in the sector, and in manufacturing. The $2 million project will take place over the next two years. Agritech's group manager in precision agriculture, Armin Werner, said they would investigate how sensors and artificial intelligence could be used to help robots understand their surroundings and adapt to them. He said they would provide enormous benefits to the primary sector, especially in dangerous industries such as forestry. "We have so many hazardous working conditions. In forestry for example, felling trees, pruning trees in very steep and harsh environments, it is a very risky work area and in the future we need to support that work with robots that can adjust to the different situations in the forest," he said.

|

Scooped by

Prentiss & Carlisle

August 28, 2017 1:21 PM

|

The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely substitute for steel - wood.

Japanese researchers and auto component makers say a material made from wood pulp weighs just one fifth of steel and can be five times stronger.

The material - cellulose nanofibres - could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.

Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs.

“Lightweighting is a constant issue for us,” said Masanori Matsushiro, a project manager overseeing body design at Toyota Motor Corp.

“But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars.”

Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota’s biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibres - made by breaking down wood pulp fibres into several hundredths of a micron (one thousandth of a millimetre).

Cellulose nanofibres have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the “Kyoto Process”, under which chemically treated wood fibres are kneaded into plastics while simultaneously being broken down into nanofibres, slashing the cost of production to roughly one-fifth that of other processes.

|

Scooped by

Prentiss & Carlisle

April 13, 2017 9:17 AM

|

Trimble Navigation Ltd. TRMB , an original equipment manufacturer of positioning, surveying and machine control products, recently acquired Canadian-based BOS Forestry. The financial details of the deal have been kept under wraps. *** Acquisitions have helped Trimble to build a comprehensive portfolio, enter new markets and generate additional revenues. The acquisition of BOS Forestry complements Trimble's Connected Forest solutions that provide full raw materials lifecycle management solutions and is expected to boost the company's forestry division. The acquisition, effective immediately, will extend Trimble's capabilities in serving its customers in the forestry business. The deal will focus on advanced technologies for better forest management, traceability and processing of timber. BOS Forestry is a leading provider of forestry software. The company's suite of applications will provide processes for scale site, log load, yard inventory, contractor settlement, finished goods sales and distribution.

|

Scooped by

Prentiss & Carlisle

February 14, 2017 10:40 AM

|

The city of Maitland is working on hammering out a way to prohibit wood-frame construction for new buildings, and looking for cities statewide to get on board to make it happen.

The Maitland City Council got behind the idea after the city’s Planning & Zoning Commission started researching it last fall. Last month the Commission requested that the City Council have the city’s lobbyist work to gain support across the state for the Florida Legislature to change Florida building code to allow cities to have more control over building materials used in its borders. The Commission’s proposal applied to all construction except detached single-family homes.

|

Scooped by

Prentiss & Carlisle

December 12, 2016 6:49 PM

|

Researchers show that the next wave of productivity improvement will come from human factors.

There has been recent concern that the continuous improvement of forest harvesting has stagnated or possibly decreased in the Nordic countries. A modern problem is not the lack of knowledge, but the inability to put the knowledge into practise. Through a literature review, researchers examined whether human factors can improve the performance of harvesting systems by simulating continued performance improvements. The researchers focussed on mechanized cut-to-length (CTL) operations, with specific reference to the operation of the single grip harvester and the harvester-forwarder system. The researchers created a conceptual framework to allow the analysis of human, technology, organization and environmental interrelated elements. The researchers discovered that the correct abilities, skills, techniques and training alone are not sufficient to ensure the high performance of a logging system.

It was discovered that education, training, semi-automation, shift scheduling, harvester-forwarder cooperation and inter- and intra- organizational knowledge exchange were all very important in order to obtain improvement and development. Automation specifically will introduce a system change that will have a similar effect on the forestry industry as that change which occurred when mechanisation was introduced into logging. Semi-automated solutions and increased decision support will pre-empt the move to automation, which is already a stated goal for countries such as Sweden. In order to gain productivity benefits, research is required into methods, interfaces, forms of interaction, risk analyses and automation technology.

The research was published in the International Journal of Forest Engineering, Vol. 27 (2), 2016. The authors are C Häggström and O Lindroos. Source:http://dx.doi.org/10.1080/14942119.2016.1170495

|

Scooped by

Prentiss & Carlisle

August 11, 2016 11:34 AM

|

Unmanned aerial systems (also referred to as UAVs or drones) have a variety of natural resources applications including forest mapping, inventory, photography, disturbance assessment, wildlife assessment, and perhaps even timber sale administration. This brief presentation will introduce common UAS formats, their capabilities and limitations, and the status of rapidly changing regulations and licensing requirements. *** Speaker: Bill Anderson, UMN Dept. of Forest Resources Date: Tuesday, August 16, 2016 12:00 PM - 1:00 PM (Central Time) Price: $20.00

|

Scooped by

Prentiss & Carlisle

May 10, 2016 10:17 AM

|

Sappi Paper’s mill in Westbrook has remained standing in the 21st century by learning to let go. The mill staked its future on paper with the key of not sticking to things, allowing paper-backed patterns to be pressed into synthetic materials, laminate flooring, leather and other products. The mill has shed thousands of jobs since hitting peak employment levels in the 1950s but carved a path to profitability through a spate of tough times and recent closures in the industry.

***

During the early 2000s, the Westbrook mill completed a long shift away from publishing markets, converting lower efficiency, turn-of-the-century paper machines to what’s called release paper, research that began when the mill was still in the hands of S.D. Warren Co. That paper, coated with various textures, can be used to create a range of products, including patterned car interiors, flooring, shoes and soccer balls.

***

Mike Standel, the mill’s managing director, said the company’s market research focuses now on forecasting quickly changing fashion trends. Those quick changes, he said, give it an advantage in competing with other methods for pressing textures into a material, such as using stainless steel belts or plates. “It’s always important to be first, and we can provide something unique that can let our customers have exclusivity or be first to market,” Standel said. The Westbrook mill produces about 40 percent of the global market for release paper, according to Standel, who said Europe and China are key markets in the business for which about 92 percent of its product is exported.

|

Scooped by

Prentiss & Carlisle

March 7, 2016 1:05 PM

|

University of Adelaide forest DNA forensics research has helped convict National Forest timber thieves in a landmark case in the United States.

Four defendants prosecuted for stealing Bigleaf maple wood from the Gifford Pinchot National Forest have pleaded guilty, in a case that marks the first time the US government has prosecuted for illegal interstate trade of wood products under the Lacey Act. The Lacey Act is a US wildlife protection law that was amended in 2008 to include plants, making it illegal to trade in illegally sourced wood products.

DNA evidence developed by a consortium of experts led by the University of Adelaide was an important element of the government's case against the timber thieves.

Researchers from the University's Environment Institute developed DNA markers for the Bigleaf maple population. They joined the US Forest Service and timber-tracking specialists Double Helix Tracking Technologies, with help from World Resources Institute, to develop the first DNA profiling reference database for the species. It's the only one of its kind for trees that has been validated for use in court proceedings.

Just like individual humans, each tree has a unique genetic fingerprint, making it possible to match pieces of sawn wood with the stumps of the trees from which they were cut, using a technique called DNA profiling.

"With this technology, wood buyers can verify whether or not Bigleaf maple has been legally harvested," says Professor Andrew Lowe, Chair of Conservation Biology at the University of Adelaide, and Chief Scientific Officer of Double Helix.

"Our database indicates that, with these markers, the likelihood of two trees having the same DNA profile is as low as one in 428 sextillion; there are thought to be approximately 70 sextillion stars in the universe."

|

Scooped by

Prentiss & Carlisle

August 19, 2015 11:13 AM

|

|

Your new post is loading...

Your new post is loading...

![7 Reasons Why Virtual Reality Technology Will Totally Disrupt the Real Estate Industry [Infographic] | Timberland Investment | Scoop.it](https://img.scoop.it/Fin1i8Skb0HZawgWDh4z5Tl72eJkfbmt4t8yenImKBVvK0kTmF0xjctABnaLJIm9)