Your new post is loading...

Your new post is loading...

|

Rescooped by

Steven Bonacorsi

from lean manufacturing

April 10, 2013 10:35 PM

|

It used to take 34 steps to open a checking account at Great Western Bank.

Via Michel Baudin

|

Scooped by

Steven Bonacorsi

April 10, 2013 10:34 PM

|

Financial Post

BDC Insight: Continuous improvement makes a difference

Financial Post

“The improvements become self-fulfilling. They come from within and people will constantly look at operations from an innovative mindset.

|

Scooped by

Steven Bonacorsi

April 10, 2013 10:34 PM

|

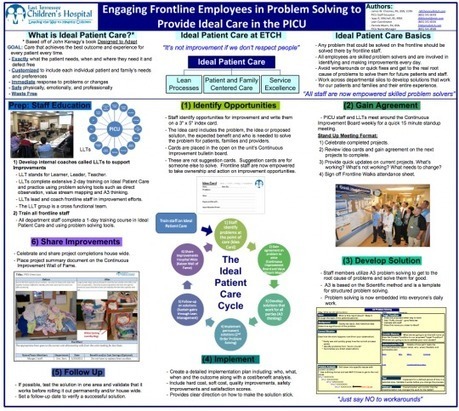

MARK GRABAN 2012 Some Recent Interviews on Lean Healthcare & Kaizen lean I was fortunate to have three interviews published in the past week, where I was talking about Lean Healthcare and Kaizen, so I thought I'd ...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:14 PM

|

Performance Cycle: The Key to Continuous Improvement Tennis Now (press release) At Ivan Lendl International Junior Tennis Academy on Hilton Head Island, student-athletes (ages 9-19) reach their potential on and off the tennis court by creating a...

|

Rescooped by

Steven Bonacorsi

from lean manufacturing

April 10, 2013 7:14 PM

|

"In the Kaizen approach, stealing the ideas of others isn’t a negative thing. If somebody else implemented an idea and you can use that idea in your area, a Kaizen organization ENCOURAGES the borrowing, stealing, adoption, and adaptation of ideas. There’s no shame in that. This idea was being preached at one hospital I visited yesterday, which was nice to see. But… USA Today had a blurb the other day about one idea you shouldn’t steal. It’s an idea that’s already proven not to work – paying bonuses based on the value of improvement ideas."

Via Michel Baudin

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:13 PM

|

Project Manager - Business Analyst - Change and Continuous Improvement GAAPweb Finance and Accounting News A commodity trading business based in Central London is looking to recruit a Continuous Improvement Project Manager on a contract basis until...

|

Rescooped by

Steven Bonacorsi

from Peer2Politics

April 10, 2013 7:12 PM

|

Presented through 10 case studies spread over four continents, Beyond Agile shows that process improvement is owned by no single process, no single school of thought, and no single culture. Whether in India, Spain, South Africa, or the United States, these teams of knowledge workers faced very similar problems, but in very different political, economic, and social environments. Their path of continuous improvement, however, was universal.

Via jean lievens

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:12 PM

|

Your opportunity to learn about Kaizen

Gympie Times

WORLD leading experts in Kaizen will present their only Australian public event in Gympie on Thursday.

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:11 PM

|

In this post, Michael Giller gives his take on what the word "quality" means to him as a sales engineer at SmartBear.

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:10 PM

|

How a Creative, Innovative Culture impacts your Continuous Improvement efforts. When one initially thinks about a continuous improvement environment they think about standardizing and streamlining with the focus entirely ...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:10 PM

|

A leading manufacturer supplying products into multiple sectors including automotive has a requirement for Business Improvement specialist to join their business as Continuous Improvement Manager at t (Continuous Improvement Manager - Staffordshire...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:09 PM

|

Successful leadership can sometimes be reduced to a small number of fundamental choices. Once those choices are made, they guide decisions and behavior in dozens of situations each week. One of tho...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:07 PM

|

Kaizen Venture Partners Job Vacancies. Job position for the above job vacancy. Call Centre Operator Qualification for this employment opportunity. Job applicants must have a Degree in English Language To apply for this ...

|

|

Scooped by

Steven Bonacorsi

April 10, 2013 10:35 PM

|

10sBalls Performance Cycle: The Key to Continuous Improvement - By Matt Cuccaro | 10sBalls At Ivan Lendl International Junior Tennis Academy on Hilton Head Island, our student-athletes (ages 9-19) reach their potential on and off the tennis court...

|

Scooped by

Steven Bonacorsi

April 10, 2013 10:34 PM

|

CHAMPION: 20 years of continuous improvement Hillcountrynews Since I came on board as superintendent of schools for Leander ISD five years ago, I've addressed the district's Continuous Improvement (CI) Conference a number of times because it is a...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:15 PM

|

A Drive for Productivity Last week I wrote a post entitled Value Creation for Private Investors that went largely ignored as it was one of my lowest viewed posts of the new year for a Monday when most of you tune in. The idea about which I wrote...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:14 PM

|

In the fall of 2009, I launched Gemba TalesTM in anticipation of the Kaizen Event Fieldbook. Truthfully, it was something that I was told authors do – “You need to have a blog to promote your book.”

Well, sort of.

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:14 PM

|

2013 IndustryWeek Best Plants Conference Features Continuous Improvement ...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:13 PM

|

Reading, Berkshire, England, South Central, United Kingdom Career Engineer Continuous Improvement Leader Berkshire Salary: �35,000-�40,000 The Company An opportunity has been created for a Continuous Improvement Leader to join a global...

Look up W. Edwards Deming on the Internet and you will learn that he revolutionized manufacturing practices If you’re a small business owner there’s a concept Deming popularized that you can apply. It’s called PDCA, for plan / do / check /act. It’s a way to improve the processes a company implements by making sure those processes produce ever-better outcomes. Let’s say you want to increase profitability by doing three things: Schedule better, train current field employees, and make sure all materials are on the job when needed. So you write a six-week plan calling for you to buy and learn a scheduling program, set up an on-site training to train workers, and start ordering materials four days ahead of needing them. Suppose you did all those things. Congratulations: You accomplished the “Plan” and “Do” parts of PDCA.

The key to success in PDCA lies in the last two components: check and act. This cycle is repeated continuously as the company matures and different problems arise. That’s why Deming’s PDCA cycle also is called “continuous improvement.”

Via Ashok Ramachandran

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:11 PM

|

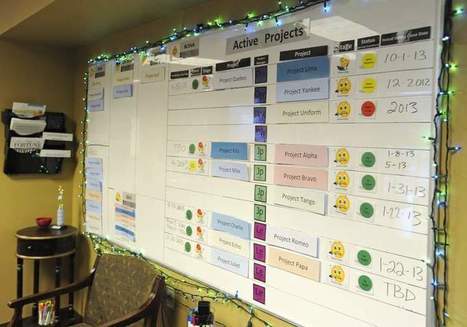

Screen Shot 2013 03 13 at 6.50.58 AM 150x150 Kaizen & Idea Boards Spotted It's great to see more healthcare organizations embracing the philosophy and methodologies of kaizen (as we documented in Healthcare Kaizen) ...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:11 PM

|

WEDNESDAY April 17, 2013 6 – 9 pm. ASQ 702 San Gabriel Valley. Presents. Continuous Improvement and Process Variations. Presented by Tarek Elneil. Any manufacturing process has five components sequentially ...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:10 PM

|

in Stafford, Staffordshire - CV-Library.co.uk (Featured Job: Continuous Improvement Manager, Stafford: A leading manufacturer supplying products into m...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:09 PM

|

one2onetracker is a Cloud based Progress and Performance Evaluation tool (Empowered by engagement, role clarity and continuous improvement http://t.co/n8fSoToEes #Leadership #TChat #HR Software)...

|

Scooped by

Steven Bonacorsi

April 10, 2013 7:08 PM

|

JT 150x150 Song Parody: You Say You Want a Kaizen Culture lean With apologies to The Beatles and Dr. John Toussaint: “Kaizen Culture” (sung to “Revolution” by The Beatles). You say you want a kaizen culture.

|

Your new post is loading...

Your new post is loading...

Your new post is loading...

Your new post is loading...

This article is focused on improvement done at Great Western Bank, a regional bank with 200 locations and 1,600 employees, inspired by similar work done at mid-size manufacturers Raven Industries and Daktronics, and contractor Muth Electric.

The improvements seem substantial. The article otherwise contains a few minor eyebrow raisers that, to be fair, may be due to misunderstandings by the reporter.

The subtitle describes Kaizen as a "Japanese method," but later explains that "the work is done in Kaizen events,..." Kaizen events are an American method and unknown in Japan. And what is implemented through Kaizen events is not what Kaizen as understood in Japan.

"Kaizen is considered the building block of lean production..." Well, I can think of a few other building blocks.

"... the resulting strategies are implemented [...] within days of the event." Kaizen events don't just identify strategies, but changes implemented primarily during the event itself, not in the days that follow.