TSMC's former co-COO Chiang Shangyi calls Intel a nobody and advises firm to merge with a mature chip manufacturing company instead .

Get Started for FREE

Sign up with Facebook Sign up with X

I don't have a Facebook or a X account

Your new post is loading... Your new post is loading...

Your new post is loading... Your new post is loading...

TECH NEWS : Pat Gelsinger's leadership at Intel ended abruptly as the company's market position deteriorated, marked by significant strategic missteps and revenue

Richard Platt's insight:

In 2024, Intel's Board of Directors (BoD) abruptly ended Pat Gelsinger's turnaround attempt, cutting short what he believed would be a 5-year transformation of the semiconductor giant. "I wasn't done with the +5 years when the board made a directional change," Gelsingertold said, revealing his frustration with a tenure that saw the company's market position dramatically erode. Gelsinger had pitched a +5-year plan to turn around Intel when he joined the chipmaker. However, just 3 years into his tenure, the board gave Gelsinger an ultimatum after it lost the confidence to either announce his retirement or face removal. Gelsinger ultimately chose retirement, bringing his tumultuous tenure, marked by what some analysts called significant strategic missteps, to an end with a bittersweet acknowledgement that the company had been "his life for the bulk of his working career." Under Pat Gelsinger’s leadership, Intel's revenue plummeted to $54 billion in 2023, nearly 1/3 below 2021 levels. The company reported its 1st annual net loss since 1986, with its stock crashing 66% from its peak during Gelsinger's early months as CEO.

AMD's new Sound Wave chip is an Arm-based APU with RDNA 3.5 GPU and MALL cache, ready for the Windows on Arm battle with Qualcomm, Intel, and soon NVIDIA.

Richard Platt's insight:

AMD's next-generation Sound Wave APU is reportedly a new Arm-based chip that will feature RDNA 3.5 GPU cores, MALL cache, and compete in the Windows on Arm market against Qualcomm, Intel, and soon NVIDIA in 2026. In a new video from leaker Moore's Law is Dead, we're hearing AMD's next-gen Sound Wave APU will feature 2 x P-Cores and 4 x E-Cores of Arm-based CPU that won't deliver powerhouse performance, but instead will have fantastic battery life as Windows on Arm laptops do. AMD is expected to use 4 x GPU cores based on the RDNA 3.5 GPU, but with improved ML (machine learning) performance that could be more of an "RDNA 3.5+" GPU instead. Sound Wave is expected to feature 16MB of MALL cache, a 4th Generation AI engine, a 128-bit LPDDR5X-9600 memory controller and 16GB of RAM expected to be the "standard" for the new Arm-based Sound Wave APU. We first heard about Sound Wave last year, rumored as a Zen 6-based APU... but things are changing, AMD is moving Sound Wave into the Arm-based CPU world, and with the crumbling Qualcomm Snapdragon X Elite-powered Windows on Arm laptops... well, AMD can come in and dominate the Arm APU market, too.

Explore the latest news, products, and insights in electronics engineering, embedded systems, VLSI, and semiconductor industries on EE Herald.

Richard Platt's insight:

Global semiconductor fab equipment spending for front-end facilities heading for a massive 18% growth in 2026 to reach US$130 Billion, and with a modest growth of 2% in 2025 to reach US$110 Billion, as per the forecast by SEMI, an industry body representing global semiconductor equipment and materials manufacturers. “The global semiconductor industry’s investments in fab equipment have been edging up for six straight years, and spending is poised to see a strong 18% increase in 2026 as production ramps to meet booming AI-related chip demand,” said Ajit Manocha, SEMI President and CEO. “This forecasted capex growth signals an urgent need for intensified workforce development initiatives throughout 2025 and 2026 to deliver skilled workers necessary for the approximately 50 new fabs expected to come online during these two years.” Advanced logic and micro takes nearly close to 50% share of semiconductor equipment market, followed by DRAM and NAND flash with around 30% share. Here is the breakup of growth-forecast for each segment by SEMI: Logic and Micro: Logic & Micro (includes advanced foundries) segment is projected to see an 11% increase in investments, reaching $52 billion in 2025, followed by a 14% increase to $59 billion in 2026. Semiconductor memory: Overall memory segment spending is expected to grow steadily the next two years, increasing by 2% to reach $32 billion by 2025, with an even stronger growth forecast of 27% in 2026. DRAM: Investments in the DRAM segment are projected to decline by 6% year-over-year, totaling $21 billion in 2025, but are anticipated to rebound with a 19% increase to $25 billion in 2026. NAND Flash: NAND segment spending is expected to recover significantly, rising by 54% year-over-year to $10 billion in 2025, and further increasing by 47% to $15 billion in 2026. China: Spending of $38 billion in 2025 representing a 24% year-over-year decrease. By 2026, spending is forecast to decline further 5% year-over-year to $36 billion. Korea: Korean investment is forecasted to grow by 29% to $21.5 billion in 2025 and by 26% to $27 billion in 2026. Taiwan:Taiwan is projected to spend $21 billion in 2025 and $24.5 billion in 2026 to meet the growing demand for AI applications across cloud services and edge devices. USA: Americas region ranks fourth, with expected spending of $14 billion in 2025 and $20 billion in 2026. Japan, Europe and the Middle East, and Southeast Asia follow in investments, projected to spend $14 billion, $9 billion, and $4 billion in 2025, and $11 billion, $7 billion, and $4 billion in 2026, respectively.

Notebookcheck has tested the new Microsoft Surface Laptop 7 15 for Business with an Intel Core Ultra 7 268V, 32 GB RAM and an IPS touchscreen.

Richard Platt's insight:

The Surface laptop is better with Intel. Last year, Microsoft switched its Surface devices completely to ARM processors from Qualcomm. But, it doesn't fit what business customers want from these devices, as the Surface Laptop 15 for Business is now available with Intel's Lunar Lake processors. The result is better in many areas. The new Surface Laptop 7 15 for Business, equipped with Intel processors, has advantages over the Snapdragon variant in a number of areas. These include better software compatibility, of course, but surprisingly also improved battery life. In addition, business customers don't seem to want Snapdragon laptops, and in general, the Intel variant is simply the better overall package. This is a pretty harsh slap in the face for Windows on ARM, especially when you consider how hard Microsoft is pushing the ARM models. Although the Lunar Lake processor delivers less multi-core CPU performance, it is on par in single-core scenarios and comes with a faster integrated graphics card as well as Thunderbolt 4. Its IPS screen boasts a high brightness and very accurate color profiles. One disadvantage remains for both models is their high surface temperatures under load, so a second fan would really make sense in this respect. The 15-inch model in particular still has quite a lot of free space in its case, which is why this technically shouldn't be a problem. It should also be mentioned that the Intel version's fan gets louder under high load, which is pretty much the only major disadvantage compared to the ARM model. Finally, there is its price, and the Intel model is around $500 more expensive, going off its MRSP. However, the ARM models are often heavily discounted, and the comparable Snapdragon configuration with 32 GB RAM and a 1-TB SSD currently costs around $1,599.99 from Microsoft itself, i.e. a whopping $1,000 less. Naturally, this difference can hardly be justified.

Gloo, a Boulder, Colorado-based firm that offers technology tools to Christian churches and other faith groups, said on Monday that Pat Gelsinger is joining the firm as its head of technology and executive chairman, where he will help the group develop AI tools such as virtual assistants and chatbots. Gelsinger is the former CEO of both chipmaker Intel and Broadcom-owned VMware. Gelsinger left Intel last year after a clash with its board over his turnaround plans.

Richard Platt's insight:

Gloo, a Boulder, Colorado-based firm that offers technology tools to Christian churches and other faith groups, said on Monday that Pat Gelsinger is joining the firm as its head of technology and executive chairman, where he will help the group develop AI tools such as virtual assistants and chatbots: Gelsinger, the former CEO of both chipmaker Intel and Broadcom-owned VMware. Gelsinger left Intel in 2024 after a clash with its board over his turnaround plans. Gelsinger's job at Gloo will be his first operational role since leaving Intel. A lifelong Christian who has helmed a group in the San Francisco Bay area working to expand church membership for more than a decade, Gelsinger has previously served on Gloo's board as non-executive chairman since 2018. Founded in 2013, Gloo last year raised $110 million in growth financing for an AI push. It is developing chatbots with a "safe search" option and answers grounded in the Christian Bible. Gelsinger will oversee Gloo's product and engineering efforts. “Technology has the power to connect, uplift, and transform lives — but only when built with purpose,” Gelsinger said.

Qualcomm has filed complaints with regulators in the U.S., EU, and South Korea, accusing Arm of restricting technology access and shifting its licensing model to undermine competition.

Richard Platt's insight:

Qualcomm has accused its longtime partner, Arm Holdings, of unfair business practices, taking the matter to U.S., EU, and South Korean regulators. The allegations claim that Arm limits access to its technologies and changes licensing models in a bid to harm competition, Arm denies the accusations. Qualcomm has reportedly filed secret complaints against Arm with the EU Commission, the U.S. FTC, and the Korean FTC. Qualcomm argues that Arm's open licensing approach helped build a robust hardware and software ecosystem. This ecosystem is now under threat as Arm moves to restrict access to benefit its IC design business, namely compute subsystems (CSS) reference designs for client and Data Center processors and custom silicon based on CSS for large-scale clients. Arm rejected the accusations, stating that it is committed to innovation, competition, and upholding contract terms. Arm called Qualcomm's move an attempt to shift attention from a wider commercial dispute between the two companies and use regulatory pressure for its benefit. Indeed, the antitrust complaints align with Qualcomm's arguments in a recent legal clash with Arm in Delaware. Qualcomm won that trial, as the court ruled that the company did not break the terms of its architecture license agreement (ALA) and technology license agreement (TLA) by acquiring Nuvia and using its IP in its Snapdragon X processors for client PCs. Arm said it would seek a retrial. However, Qualcomm wants to ensure that it will have access to Arm's ISAs and technologies by filing complaints with antitrust regulators. “Arm remains focused on enhancing innovation, promoting competition, and respecting contractual rights and obligations," Arm said in a statement "Any allegation of anti-competitive conduct is nothing more than a desperate attempt by Qualcomm to detract from the merits and expand the parties’ ongoing commercial dispute for its own competitive benefit. Arm is confident that it will ultimately prevail in this dispute.”

As China seeks to cut reliance on Western chipmaking machines such as extreme ultraviolet (EUV) lithography systems, the country has been pushin

Richard Platt's insight:

As China seeks to cut reliance on Western chipmaking machines such as extreme ultraviolet (EUV) lithography systems, the country has been pushing existing deep ultraviolet lithography (DUV) to its limits. According to Bloomberg and South China Morning Post, Huawei-linked SiCarrier may enable domestic 5nm chip production with its self-aligned quadruple patterning (SAQP) technology. South China Morning Post notes that SiCarrier grabbed headlines in 2023 with a patent for making 5nm chips using DUV tools—a breakthrough linked to Huawei’s 7-nm chip in the Mate 60 Pro. The EUV machine, which uses laser-induced discharge plasma (LDP) technology, is set for trial production in Q3 2025, with mass manufacturing aimed for 2026. China’s new system under testing uses the LDP approach to generate 13.5 nm EUV radiation by vaporizing tin between electrodes and converting it to plasma through high-voltage discharge, with electron-ion collisions producing the required wavelength. Notably, Bloomberg indicates that Chinese chip equipment makers like Naura and Advanced Micro-Fabrication Equipment are also exploring etching systems to complement multiple patterning for 7-nm and beyond, as EUV remains out of reach.A Nikkei report seems to be less optimistic, noting that SiCarrier claims to have built lithography machines for 28-nm or older nodes, a market currently led by ASML, Nikon, and Canon. However, sources told Nikkei that its ability to commercialize them remains uncertain.

Richard Platt's insight:

While recent reports suggest TSMC's 2nm trial production is progressing steadily, DIGITIMES Research analyst Luke Lin cautions that actual yield rates will vary depending on the chip design—meaning different readiness timelines for customers like Apple, Nvidia, and AMD.

Richard Platt's insight:

During a visit to participate in the China Development Forum, Samsung Electronics chairman Lee Jae-Yong and Qualcomm CEO Cristiano Amon reportedly visited Xiaomi's factory in Beijing to meet with Xiaomi's top executives Lei Jun and Lin Bin. The visit has sparked speculation about a potential collaboration between Samsung and Xiaomi in automotive electronic components, despite their competition in the smartphone and home appliance markets.

It seems like NVIDIA has admitted to the tough competition they are facing from Huawei, as Jensen says that the firm cannot be ignored.

Richard Platt's insight:

It seems like NVIDIA has admitted to the tough competition they are facing from Huawei and its AI chip in China, as Jensen says that the firm cannot be ignored now. One of the bigger revenue sources for NVIDIA is its dominance over China's AI market, given that not only were the company's solutions in the industry present from the very start, but Team Green essentially didn't give domestic competitors any space. However, with the US export restrictions hitting, it marked the beginning of NVIDIA facing strict competition from "in-house" AI chips by the likes of Huawei, and while Jensen previously didn't admit Huawei's influence over their Data Center and AI revenue from China, it seems like he has realized that Huawei isn't here to play.Huawei is the "single most formidable technology company" in China. The firm's presence in AI is growing every single year. They have conquered every market they've engaged in. The markets indicate that Huawei cannot be stopped for now. The Chinese firm is on track to release its next-gen Ascend 910C AI chip in the next quarter. It is said to feature performance on par with NVIDIA's H100 AI accelerators, and that too at better pricing and availability. Moreover, the semiconductor supply chain in China is positioned more dominantly than it was a few years ago, which means that NVIDIA's leverage over Huawei is decreasing with time.To top it all off, with the US's growing concern over China's AI progress, it is imminent that NVIDIA will experience further export restrictions, whether in the form of cutting down its existing AI hardware options available to China or completely halting them from exporting. This means that domestic AI solutions in China will rise tremendously, and major tech firms will ultimately be forced to adopt them. Out of all the names, Huawei is the one that stands out the most. Huawei has been a target of US restrictions since Trump's first term, and despite several attempts to reduce the company's influence over the tech world, the Chinese firm keeps coming back stronger than before. And for NVIDIA, they need to do something to maintain their relevance in Chinese markets.

TAIPEI -- A Chinese semiconductor equipment maker linked to Huawei has been quietly developing a wide range of machines to replace offerings by ASML a

Richard Platt's insight:

China's Accelerated Indigenization: Driven by US export controls, China is aggressively pursuing self-sufficiency in semiconductor manufacturing equipment.

Circumventing Export Controls:

Talent Acquisition:

Market Share Erosion:

Mature Node Advancement:

Richard Platt's insight:

Foxconn, the world's largest EMS (Electronics Manufacturer Services) , contractor announced record-breaking revenue for 2024, reaching US$216 billion. The milestone, revealed by Chairman Young Liu during a recent earnings call, marks the highest annual revenue in the company's history. |

If everything goes well, Samsung could end up becoming the first foundry in the world to deliver 2nm chips, beating TSMC

Richard Platt's insight:

The troubles that Samsung experienced with its 3-nm GAA technology have not been repeated with its 2-nm GAA node. At least, so far, hinting that Samsung Foundry may have finally managed to overcome the SNAFUs, making it lose its edge in this race. The trial production run of its Exynos 2600 on the 2-nm GAA yields has reached 30% and could be near ready to commence full-scale wafer production, depending on whether it can scale those yields to acceptable levels. No telling how much Samsung’s 2nm GAA yields have improved since its pilot build had touched 30%, but the Exynos 2600 prototype is to be fabbed and enter production in May this year. This head start will give Samsung the necessary breathing room to ensure that it can slowly improve its yields and make mass production viable. Bare minimum, the 2-nm GAA node needs at least a yield of 70% to start accepting customer orders. Exynos 2600's design needs to be completed by Q3 2025 to have a sliver of a chance of finding a place in the upcoming Galaxy S26 series. Even if Samsung can get an edge against TSMC regarding the launch timeline, Samsung has held this advantage before when it announced the 1st-gen 3-nm GAA node back in 2022, nothing is guaranteed when comparing yields, especially when history can repeat itself.

TSMC has chosen the US as its next place of expansion, as the firm has now revealed that it plans to produce cutting-edge chips in Arizona.

Richard Platt's insight:

Well, it seems like TSMC has chosen the US as its next place of expansion, as the firm has now revealed that it plans to produce cutting-edge chips in Arizona. According to TSMC's VP, Peter Cleveland claimed that the company plans to produce its third fab in Arizona to sustain the "US AI leadership" and ensure that America becomes a 2nd home for TSMC, apart from Taiwan. By these statements, the idea of a "technology transfer" certainly looks evident. "We have not started to break ground on our 3rd wafer fab in Phoenix. We would like to start next week. We're going to build those (high-end chips) in Phoenix to sustain the U.S.'s AI leadership." - TSMC. The VP also believes that the US will account for 75% of TSMC's business in the longer run, and the Trump administration has played a key role in catalyzing this process. It seems like Trump's pressure tactics have worked out in restoring the US's chip glory, although this will take years from now on. Based on what we know, TSMC's A16 (1.6nm) will likely arrive on the market by H2 2026, which means the process will be available for production in the US two years after Taiwan. While the delay is undoubtedly there, it does show that the US won't be deprived of advanced nodes and that, in the longer run, the nation could play a massive role in the semiconductor industry's dynamics.

To maintain peak competitiveness with Apple, a rumor claims that Qualcomm will use the 2nm process for its Snapdragon 8 Elite Gen 3 in 2026

Richard Platt's insight:

Apple will likely be TSMC’s first customer for the latter’s 2nm process technology to mass-produce the A20 for 2026's iPhone 18 series. TSMC is reportedly accepting orders for its next-gen node. According to one rumor, Qualcomm plans to leverage the 2nm process for two chipset releases in 2026, one of which will likely be the Snapdragon 8 Elite Gen 3. The second chipset release mass-produced on TSMC’s 2nm technology could be a downgraded version of the Snapdragon 8 Elite Gen 3. The rumor (from Digital Chat Station) mentions that the SM8950, presumably the Snapdragon 8 Elite Gen 3, will arrive in 2026 and be fabricated on improved lithography. As for the SM8945, we guess that this SoC will be a less powerful version of the Snapdragon 8 Elite Gen 3, utilize the same node, but it could sport a less capable GPU or downclocked CPU cores. The SM8945 could be one of the ‘Snapdragon 8s’ members, which Qualcomm would probably call the Snapdragon 8s Gen 6. TSMC is not the only foundry pursuing the goal of garnering orders from lucrative customers, though its chance of accumulating orders has increased because its trial production run reported about a week ago hit yields of 60%, suggesting that the yields are higher now. Samsung is racing to achieve favorable yields, with its 2nm GAA process, said to have touched 30% yields during a trial run of the Exynos 2600. Given each wafer is estimated to cost $30,000/unit, it is no surprise that Qualcomm has been reported to be exploring a dual-sourcing option where it utilizes technologies from both TSMC’s and Samsung’s foundries to lower production costs. However, this approach is only viable if Samsung can improve its 2nm yields. Sadly, Digital Chat Station once mentioned that Qualcomm has little choice but to exclusively place Snapdragon 8 Elite Gen 2 and Snapdragon 8 Elite Gen 3 orders with TSMC. Assuming a change in Qualcomm’s plans, we will update accordingly.

TSMC has reportedly got 2nm chip orders from Apple while Samsung Foundry for other customers to be confident in its process. - SamMobile

Richard Platt's insight:

Samsung Foundry has ambitions of taking a big chunk out of TSMC's market share but it's not even close. As of Q4 2024, TSMC's share of the global foundry market hit nearly 70%, more than double that of Samsung's and it's showing no signs of slowing down. Samsung Foundry is having to grapple with yield and quality issues that seem to have led to a loss of confidence in customers. It would have hoped that things get better as chipmakers get their 2nm chips out, but their orders are going in TSMC's lap for now. A new report from a noted analyst highlights that Apple's custom IC for 2026's iPhone 18 will be made on TSMC's 2nm process. It's further claimed that TSMC's 2nm trial yields hover between 60-70%, which is incredible as it goes to show the Taiwanese corporation is ready to hit the ground running. Apple has typically opted for TSMC to make its chips and it's unlikely that it would have gone Samsung Foundry's way to get its next-generation custom mobile chip made. However, Apple locking in production capacity at TSMC so far out is a vote of confidence that other chipmakers will most certainly take note of. Samsung needs to turn things around after its 3nm process has failed to win any major orders. Yield issues have consistently plagued the process and burned billions in cash. There has been hope that perhaps NVIDIA and Qualcomm might choose Samsung Foundry to get some of their 2nm chips made. However, if Samsung isn't able to satisfactorily demonstrate that the same issues that made the 3nm a disaster won't reappear with the 2nm, then it may just have to watch again as TSMC rides off into the sunset with the order book.

Richard Platt's insight:

The recall of every vehicle is the ultimate brand embarrassment. It already seemed clear that the Tesla Cybertruck was a flop commercially when the company started offering incentives and even resorted to a desperate sales pitch on the White House lawn. It's also no news that the EV pick-up truck has design flaws, from frames snapping to the strange light positioning and an inability to handle snow. The car isn't even road legal in many countries. But just when it seemed the Cybertruck's reputation couldn't fall any further, Tesla now suffered the ultimate embarrassment for its brand. It's had to recall every single vehicle. It's because panels have been flying off on the road since they're merely stuck on with glue. Tesla has agreed to recall all 46,100 Cybertruck pickups currently out there after the US traffic safety administration, NHTSA, raised concerns about the glue used to hold exterior sheet metal. The NHTSA received a complaint from an owner after a panel lining the side of the roof came loose. The adhesive, it seems, can become brittle, particularly in cold conditions, causing a major accident risk. Sadly, the news is hardly surprising. The design flaw has been pointed out in videos on social media like the X post above for months. The car enthusiast Tesla says it will replace the original bonding agent with a different structural adhesive that, according to the NHTSA recall report, won't be "prone to environmental embrittlement". That doesn't exactly inspire confidence, though; those panels are still stuck on with glue. The Cybertruck was long delayed due to engineering problems, and it massively increased in price while being downgraded in specs from the original 2019 concept. There have already been recalls to fix software and hardware, and deliveries are nowhere near the company's initial projections of 500,000 units/year. To cement the vehicle's disgrace, there have been reports of Cybertruck owners trying to sell their vehicles, either out of embarrassment at the car or horror at Musk's support for far-right political groups. The Cybertruck debacle has also distracted Tesla from the potentially much more bankable Model 2, which it first teased five years ago. The increasing controversy of Musk's role as advisor to Donald Trump could now harm the prospects of the upcoming entry car if it ever reaches production. While Musk's entry into government might make sense for his personal goals, it's not been great for this brand. Tesla shares have lost a third of their value since the start of the year. The company's been dropped from the Vancouver International Auto Show because of security concerns, and even big Tesla bulls like the tech analyst Dan Ives are saying Musk needs to pull back from the Department of Government Efficiency (DOGE) if he's to save Tesla. “The brand damage started as limited in our view based on our initial survey work… but now has spread globally over the last few weeks into what we would characterise as a brand tornado crisis moment for Musk and Tesla,” Ives wrote in a note to investors. It may be the case that Musk thinks the reputation of the Tesla logo in the car market no longer matters too much as the company aims to move towards tech innovations like its robotaxi and humanoid robots. Surely EVs are kind of 'woke', anyway?

Richard Platt's insight:

Instability woes continue to trouble Nvidia's RTX 40 series GPUs after 3 months, as reported by many users across different forums. Now Nvidia's R570 branch of GPU drivers have come with several instability issues with reports suggesting the impacts were felt by the older RTX 40 GPU architectures, as well. A few hotfixes down the road, Nvidia has pushed fixes for these black screen issues specifically for the RTX 50 series. However, it appears that older GPUs continue to suffer. To voice growing concern, a user at r/hardware has compiled a comprehensive list featuring numerous testimonies from affected RTX 40 and RTX 30 series users. Multiple reports indicate recurring symptoms, with impacted customers still awaiting a response from Nvidia. The community has found several workarounds, with a few common fixes including rolling back drivers, disabling Frame Generation and/or G-Sync, downgrading the DLSS version, and lowering refresh rates, among other related Band-Aid solutions. Even if Nvidia's software division is presumably cooped up with finetuning RTX 50 drivers, complete silence on these concerns is reflecting badly. These issues have been troubling RTX 40 series owners for almost three months, with no definite or official resolution. Nvidia has addressed several compatibility issues in multiple driver releases across its R570 software, however, most of them are only applicable to the RTX 50 series. Downgrading drivers is a double-edged sword, as you'll be locked out of many newer features. Nvidia is not officially acknowledging these concerns, as the "Known Issues" section under almost every new driver release fails to mention anything related to the RTX 40 series.

Despite comments suggesting high costs in the U.S., analysts found that producing chips at TSMC's Arizona fab costs less than 10% more than in Taiwan.

Richard Platt's insight:

It is equipment, not labor that defines chipmaking costs. Comments made by TSMC founder Morris Chang about high fab building costs in Arizona and higher operating costs in the U.S. created the impression that producing chips in America is way too expensive to be financially viable. However, analysts from TechInsights believe that this is not the case. According to the firm's recent study, the costs of wafers at TSMC's Fab 21 near Phoenix, Arizona, are only about 10% higher than those of similar wafers processed in Taiwan. "It costs TSMC less than 10% more to process a 300mm wafer in Arizona than the same wafer made in Taiwan," wrote G. Dan Hutcheson. The dominant factor of semiconductor production cost is the cost of equipment, contributing ++2/3 of overall wafer expenses. Tools made by leading companies like ASML, Applied Materials, KLA, Lam Research, or Tokyo Electron cost the same amount of money in Taiwan and the U.S.; they effectively neutralize location-based cost differences. A major source of confusion about wafer prices comes from labor costs. Wages in the U.S. are roughly 3X of those in Taiwan, which many mistakenly take as a significant factor in chip production. However, with the advanced automation of today's wafer fabrication facilities, labor accounts for less than 2% of the total cost. The overall expense gap between operating costs of a fab in Arizona and Taiwan is minimal despite big differences in salaries and other local costs.

Artificial intelligence (AI) is now the primary growth driver for the global semiconductor industry. With AI-related demand expected to surge further in 2025, semiconductor equipment spending is on track for another major expansion. Against the backdrop of escalating US sanctions, China is positioning itself to leverage the AI boom as a possible rebound strategy, drawing intense global attention to its next move.

Richard Platt's insight:

Artificial intelligence (AI) is now the primary growth driver for the global semiconductor industry. With AI-related demand expected to surge further in 2025, semiconductor equipment spending is on track for another major expansion. Against the backdrop of escalating US sanctions, China is positioning itself to leverage the AI boom as a possible rebound strategy, drawing intense global attention to its next move.

Richard Platt's insight:

The European semiconductor industry is urging the European Commission (EC) to update the European Chips Act, broadening its scope beyond manufacturing to include chip design, materials, and equipment. Industry leaders stress that a more comprehensive strategy is critical to reinforcing Europe's semiconductor ecosystem and maintaining global competitiveness.

At its 2025 China Partner Conference, Huawei outlined its roadmap for the next phase of artificial intelligence, spotlighting AI agents designed for autonomous planning and execution across industries. David Wang, Executive Director and Chair of Huawei's ICT Infrastructure Managing Board, reported that 2024 revenue reached CNY860 billion (US$118.5 billion), up 22% from the previous year. Sales to government and enterprise clients in China rose over 25%, becoming a key growth driver.

Richard Platt's insight:

At its 2025 China Partner Conference, Huawei outlined its roadmap for the next phase of artificial intelligence, spotlighting AI agents designed for autonomous planning and execution across industries. David Wang, Executive Director and Chair of Huawei's ICT Infrastructure Managing Board, reported that 2024 revenue reached CNY860 billion (US$118.5 billion), up 22% from the previous year. Sales to government and enterprise clients in China rose over 25%, becoming a key growth driver.

Kunimasa Suzuki, chairman of Intel KK, the Japanese subsidiary of US semiconductor giant Intel, will retire at the end of March 2025. However, he will continue to serve as chairman of the Semiconductor Assembly Test Automation and Standardization Research Association (SATAS).

Richard Platt's insight:

Kunimasa Suzuki, chairman of Intel KK, the Japanese subsidiary of US semiconductor giant Intel, will retire at the end of March 2025. However, he will continue to serve as chairman of the Semiconductor Assembly Test Automation and Standardization Research Association (SATAS).

Richard Platt's insight:

The Japanese government has approved a legislative amendment allowing the state to inject massive funds into the semiconductor startup Rapidus. According to Asahi Shimbun, Hiroki Inoue, a senior research fellow at the Japan Machinery Industry Promotion Association who has observed the semiconductor industry for over 30 years, is concerned that pursuing cutting-edge semiconductor miniaturization is an "outdated concept." He points out that industry strategies have evolved, yet Japan remains stuck in the "big battleship doctrine" mindset.

Inoue also argues that Rapidus’ decision to focus on 2nm process technology is already "outdated." As Moore's Law slows down, the benefits of further miniaturization are diminishing. He suggests that Japan should shift its focus to advanced packaging, which is closely related to semiconductor manufacturing equipment and materials—areas where Japanese companies hold a competitive advantage. Investing in this sector would yield significant results with lower capital requirements. He advises Rapidus to pause its mass production plans and concentrate its resources on R&D instead of rushing into the highly risky mass production phase.

The estimated funding required for Rapidus is 5 trillion yen, yet private investment contributions have only reached 7.3 billion yen, with no further increases. This indicates that no private investors are willing to take on this project. Koga noted that while many corporate executives attended the groundbreaking ceremony for Rapidus' factory in Chitose, Hokkaido, most were representatives from companies selling semiconductor manufacturing equipment—purchased with large amounts of taxpayer money.

|

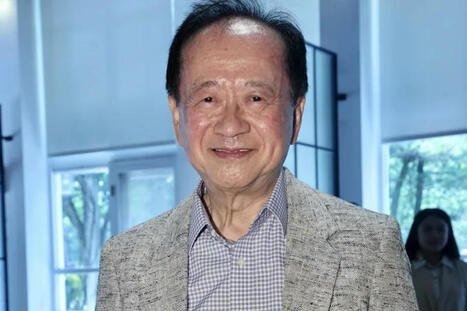

TSMC's former co-Chief Operating Officer, Chiang Shang-yi, didn't hold back when talking about Intel's chip manufacturing woes at an event in Taiwan. Chiang advised Intel to move into mature chip manufacturing processes to win, as it was too far behind TSMC to catch up. Chiang added, while Intel was formerly a "King" of the IC industry, it was now a "Nobody." With Intel's new CEO, Lip-Bu Tan, settling into his role, the firm has 2 primary objectives. The 1st is to establish regular production of its 18A chip manufacturing node, and the 2nd is to set up a robust foundry business. Both of these are aimed at competing with TSMC. Should Intel execute with the former, then it will have achieved manufacturing node parity with TSMC, which also plans to place the comparable 2-nm process into HVM in 2025. While Intel might try at another turnaround attempt, TSMC's Shang-yi believes that Intel would be better suited to focus on more mature manufacturing process nodes, instead of competing with TSMC on the high-end nodes, Intel should merge with a company that does not produce leading-edge chips but instead churns out mature process chips in large volumes. As for TSMC, he believes that the firm's biggest advantage lies in its 100s of customers. To serve the voluminous customer base, TSMC has established high output and quick manufacturing speeds, which are its key competitive advantage. Shangyi said TSMC's global dominance and success over UMC (another Taiwanese contract manufacturer) was the firm's focus on R&D. While UMC worked with IBM for research purposes, TSMC self-developed the capabilities. He recalled fondly how hard he worked to overcome Intel's dominance and is happy after witnessing TSMC doing so.