Your new post is loading...

Your new post is loading...

|

Scooped by

Mickael Ruau

July 15, 2020 11:45 AM

|

A water spider is a Lean production personnel role centered around timely and accurate stock replenishment. The water spider team member is much like a mobile Kanban system that refills the production line with the required materials to maintain a steady flow.

The person filling a water spider position needs to have a good understanding of the process, excellent communication skills, and has got to be able to follow standardized routes.

The water spider term was inspired by an insect known as a whirligig beetle, Mizusumashi in Japanese. Whirligigs appear to be able to hang between the water and the air while quickly going from place to place, keeping both of the environments in their sight simultaneously. How a water spider stock manager moves about the production floor, and the way they perceive all production steps at once, resembles the beetle’s movements and sight, giving the role its name.

|

Scooped by

Mickael Ruau

July 15, 2020 10:49 AM

|

Using a project management methodology to streamline work is good. But what happens when you combine Kanban and Lean Six Sigma? A match made in project management heaven! Learn more.

|

Scooped by

Mickael Ruau

July 10, 2020 12:55 PM

|

It’s important to know what kind of Lean Six Sigma project you’re considering. These are 5 classic project types to help you decide. If you’re looking to conduct a Green Belt or a Black Belt project, then you should be working…

|

Scooped by

Mickael Ruau

July 3, 2020 11:51 AM

|

Options Thinking lead us to invest time and money in delaying decisions to a time where we know the most about it; the extreme application of the Decide a

|

Scooped by

Mickael Ruau

June 22, 2020 10:55 AM

|

Dans une investigation (diagnostic, audit, évaluation...) il est nécessaire de comprendre le périmètre à l'aide d'une vision synthétique et macroscopique. Le SIPOC (acronyme de Supplier Input Process Output Customer) est une forme de cartographie fournissant les éléments essentiels à une première vision macroscopique.

|

Scooped by

Mickael Ruau

June 1, 2020 4:30 AM

|

Do you want to know how to drive your costs down effectively? In this article, we will explain 7 lessons how the SpaceX use concept fro

|

Scooped by

Mickael Ruau

April 10, 2020 3:15 AM

|

En 2007, alors qu’Operae sponsorisait la 1ère conférence “Agile France”, les développeurs de cette époque lointaine se demandaient si l’agile n’était, au fond, pas autre chose que du lean management appliqué au monde du logiciel. Ne créons pas de suspens : la réponse est définitivement non et beaucoup d’entreprises peuvent en témoigner. Cet article vise…

|

Scooped by

Mickael Ruau

January 10, 2020 5:14 AM

|

Reading further along in the article, you learn they solved this problem by scoring each feature (on a scale of 0 to 3) how well each feature met twenty-two key attributes from the perspective of both the business and the system. The features that scored the highest were moved to the top of the prioritization queue and the ones which scored the lowest moved to the bottom. What broke the logjam for them was having the ability to talk about the features using data and moving away from advocacy. What Brandon described is essentially Pugh Concept Selection – a Design for Six Sigma tool. Bernie Thompson gives an excellent description on his blog of using a more “pure” application of Pugh to select between different cell phone plans. Pugh was originally used to rank various design alternatives during Analyze, but again the Lean world has yet another mature tool that the Agile community can apply in our lightweight environments.

|

Scooped by

Mickael Ruau

December 9, 2019 10:55 AM

|

The all-new control chart highlights differences in estimate and delivery time so your team can continually make better estimates and deliver more reliably.

|

Scooped by

Mickael Ruau

November 26, 2019 4:55 AM

|

Apprenez comment mettre oeuvre concrètement la méthode mise au point par ce célèbre qualiticien. Un outil très utile pour tous les services de l'entreprise.

|

Scooped by

Mickael Ruau

November 19, 2019 8:02 AM

|

Vous souhaitez mettre en place une démarche d'amélioration continue dans votre entreprise ? ➜ Découvrez les 56 méthodes les plus performantes !

|

Scooped by

Mickael Ruau

November 19, 2019 7:52 AM

|

Deploying Statistical Process Control is a process in itself, requiring organizational commitment across functional boundaries. The flow-chart below outlines the major components of an effective SPC effort. The process steps are numbered for reference.

|

Scooped by

Mickael Ruau

November 19, 2019 6:13 AM

|

To apply Six Sigma to your business and produce the best results, you need to understand what Six Sigma is, the principles of Six Sigma, and the DMAIC problem-solving method. The correct tools and use of the Six Sigma scale and methods will keep your data dependable and reusable.

|

|

Scooped by

Mickael Ruau

July 15, 2020 11:15 AM

|

Curious to find out how was the decision that Kanban is appropriate for software development made? Read this brilliant BBC Worldwide case study on lean software management to find out.

|

Scooped by

Mickael Ruau

July 10, 2020 1:00 PM

|

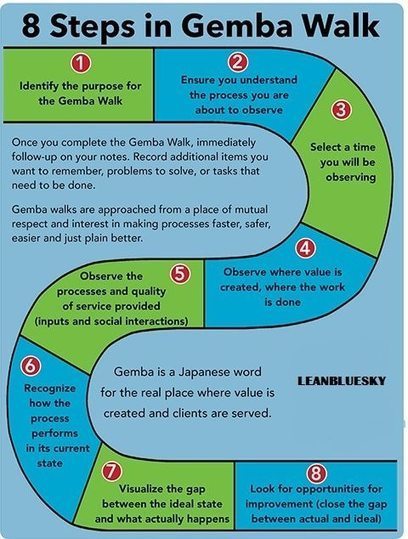

The Gemba Walk Slide. #lean

|

Scooped by

Mickael Ruau

July 10, 2020 2:13 AM

|

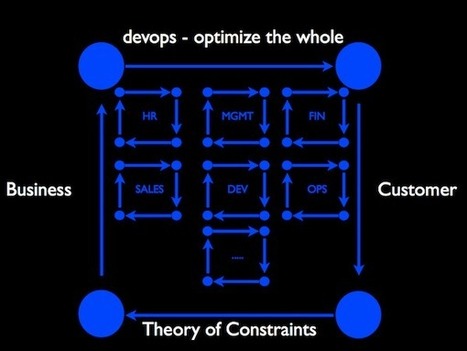

Barry Chandler, DevOpsDays London Organizer, reviews how DevOps is measured, as well as the Japanese lean engineering practices it evolved from.

|

Scooped by

Mickael Ruau

June 30, 2020 8:38 AM

|

Nous vous expliquons tout sur la méthode D.M.A.I.C. et à qui elle est destinée. Vous pourrez gérer vos projets efficacement et en toute simplicité.

|

Scooped by

Mickael Ruau

June 5, 2020 11:24 AM

|

Il est parfois nécessaire de revenir aux basiques du Lean pour mieux rebondir. Voici donc les principes de bases de la philosophie du TPS ( Toyota Productive System ). Prenons en le meilleur pour innover et avancer dans nos démarches de performances et de Lean. Principe n ° 1 «Fondez vos décisions de gestion sur En savoir plus surLean : Les 14 Principes de Toyota[…]

|

Scooped by

Mickael Ruau

May 27, 2020 5:41 AM

|

As Agile at scale continues to gain momentum, the need for a better understanding of Lean is becoming more important. The reason for this is due to what each body of knowledge is primarily focused on. As part of any of our education efforts dealing with Agile at scale (or even across a couple of… Read More »

|

Scooped by

Mickael Ruau

March 13, 2020 3:11 AM

|

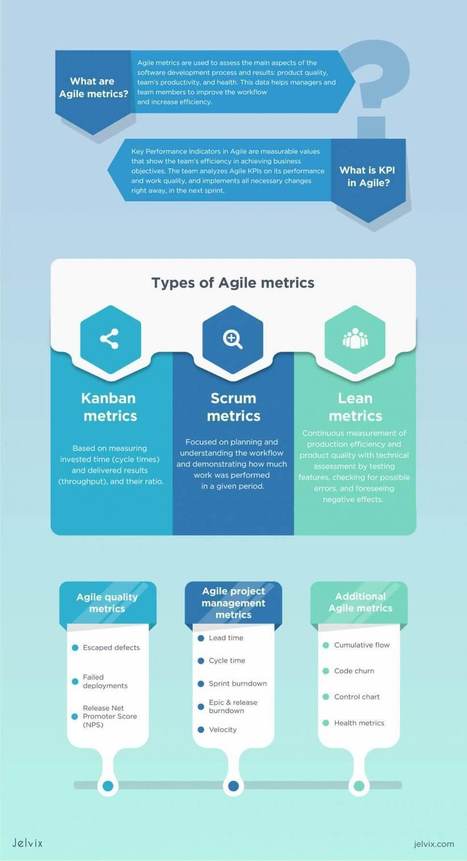

Agile metrics should save the team’s time, not consume it with unnecessary calculations. Here are the main Agile KPIs we use to measure our efficiency.

|

Scooped by

Mickael Ruau

January 8, 2020 5:33 AM

|

Many companies have a major opportunity to optimize efficiency and minimize waste in the development of their software using lean software development practices, yet many have simply not discovered the methodology. For those who have attempted to adopt this concept, most discussions and literature don’t provide specific, easy-to-follow practices for implementing lean software development. This Refcard fills the gap by covering a step-by-step approach to carrying out a lean software development process, including best practices to streamline your technology value stream.

|

Scooped by

Mickael Ruau

November 30, 2019 5:17 AM

|

Multi vari chart can be simply called graphical presentation of ANOVA data. Some call it a visual alternative to Analysis of Variance.

|

Scooped by

Mickael Ruau

November 25, 2019 6:04 AM

|

Un des piliers du fonctionnement efficace d’une équipe agile est l’amélioration continue. On pense alors recueil de feedbacks, organisation de rétrospectives, suivi de plans d’actions, etc.

Mais pourquoi attendre la rétrospective et son plan d’actions mis à jour pour améliorer une pratique ? Comment passer à la vitesse supérieure ? Comment passer d’une démarche soutenue par une méthode à une culture de l’amélioration continue ?

Les Toyota Kata, formalisés par Mike Rother, peuvent vous aider. Ces Kata sont des routines structurées qui incitent les personnes à développer une activité d’amélioration par la résolution de problème quotidienne et non plus périodique, réalisée par tous et dont l’objectif n’est plus l’élimination des sources de gaspillage mais l’atteinte d’objectifs stratégiques ambitieux.

Venez expérimenter les principes du “Improvement Kata Exercise” via un atelier accessible même aux enfants visant à développer :

- La pensée scientifique et créative afin de générer et affiner des solutions aux obstacles grâce à l'expérimentation.

- La collaboration : travail en équipe pour atteindre un prochain objectif sur la voie d'un défi plus ambitieux.

- La communication : organisez vos idées, vos données et les résultats et partagez-les efficacement.

Documents à imprimer disponibles ici : https://drive.google.com/file/d/1pYzYLz_6kP2I9G7EELeM5YNaJh54_z3j/view?usp=sharing

|

Scooped by

Mickael Ruau

November 19, 2019 7:54 AM

|

Identifying distributions is an important step in determining the correct statistical methods to apply in in Six Sigma analysis.

|

Scooped by

Mickael Ruau

November 19, 2019 7:39 AM

|

The multivari tool shows you variation (the enemy!!!) by separating it into three possible sources (within-piece, piece-to-piece, and time-to-time.)

|

Your new post is loading...

Your new post is loading...

Your new post is loading...

Your new post is loading...