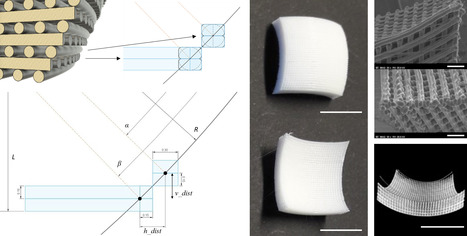

The irreversible progressive nature of degenerative osteochondral defects, affecting both articular cartilage and the subchondral bone, is a leading cause for joint disease and disability among adults, resulting in severe limitations for people to perform daily activities and represents a heavy economic burden for society. Current treatments do no provide adequate long-term solutions and innovative tissue engineering strategies are regarded as a promising alternative to improve clinical outcomes. A key aspect that needs to be considered is the integration between native tissue and the tissue engineered construct. In this recent article resulting from a collaboration between researchers from iBB and CDRSP-Politécnico de Leiria, published in the Journal Polymers, a new approach to design and manufacture curved scaffolds to mimic osteochondral tissue geometry was presented. The curvature of the sphere was proposed as a template and a procedure was developed for an automated design of scaffolds with explicitly defined curvatures. Fused filament fabrication (3D-Printing) was used for scaffolds’ manufacturing. A Shape fidelity analysis implemented through micro-CT and SEM imaging validated the maximum curvature printability limit predicted from CAD modeling and confirmed the suitability of fused filament fabrication to manufacture curvature-featuring scaffolds. Additionally, a mechanical analysis was conducted with printed scaffolds and through finite element analysis to determine scaffold mechanical properties and identify the regions more susceptible to higher loads.

Your new post is loading...

Your new post is loading...

check full paper here.